Services

SHEETING

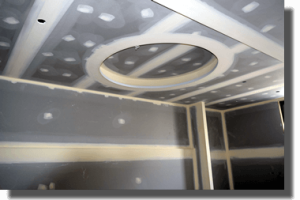

The correct installation and fixing of sheets, carried out by our knowledgeable and experienced team, guarantees a reliable plastering foundation. Sheets are set out to ensure best coverage and to minimize butt joints and waste. In residential construction, plasterboard is required to be applied horizontally in order to achieve a level of plastering finishes classed as 3,4 or 5.

SETTING

We deliver a three-coat system. All internal angles are jointed using paper tape. External corners are strengthened with perforated metal angles before they’re stapled and finished. By achieving a flatter finish and reducing surface buildup of compound, each jointing coat is widened so that the final coat of the finished joint is no less than 300mm wide.

SANDING

Dust-free vacuum sanders are used for the end result and provide the benefit of reinforcing the outcome of our quality finish. All joints are blended into the surrounding surface. Sanding blocks are then used for internal corners, leaving them square and flush.

CORNICE

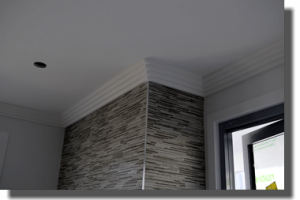

In the Brisbane residential construction sector, the most commonly used cove is a 90mm paper-faced profile. Understanding the needs of each individual customer, we provide supply and installation of all ranges of paper-faced cornice profiles and a wide range of cast cornices. Installation is fast, neat and beautifully complements our finished product.

The correct installation and fixing of sheets, carried out by our knowledgeable and experienced team, guarantees a reliable plastering foundation. Sheets are set out to ensure best coverage and to minimize butt joints and waste. In residential construction, plasterboard is required to be applied horizontally in order to achieve a level of plastering finishes classed as 3,4 or 5.

We deliver a three-coat system. All internal angles are jointed using paper tape. External corners are strengthened with perforated metal angles before they’re stapled and finished. By achieving a flatter finish and reducing surface buildup of compound, each jointing coat is widened so that the final coat of the finished joint is no less than 300mm wide.

Dust-free vacuum sanders are used for the end result and provide the benefit of reinforcing the outcome of our quality finish. All joints are blended into the surrounding surface. Sanding blocks are then used for internal corners, leaving them square and flush.

In the Brisbane residential construction sector, the most commonly used cove is a 90mm paper-faced profile. Understanding the needs of each individual customer, we provide supply and installation of all ranges of paper-faced cornice profiles and a wide range of cast cornices. Installation is fast, neat and beautifully complements our finished product.

By working with clients on their construction developments from plan stage through to fully-completed projects, we’re able to provide helpful and cost-saving advice throughout the process. Our broad range of experience becomes a resource to our clients to draw upon as they progress through construction. We encourage you to contact us with your construction plans and look forward to providing you with an obligation-free quote.